Betterworld.Solutions

The Magazine

Issue 1 October 2021

2

In This Issue

Welcome to Betterworld.Solutions 3

Have You Got 7 Minutes to Save The World? 3

Catch the Big Train to Net Zero 4

The Yorkshire Climate Change Summit 2021 4

The Clock’s Ticking - And Not Just For The Planet 6

If a Rainforest Falls And No-One Listens... 7

The Soft Power Of Voltage Optimization 9

The Monstrous Problem of Covid Waste 10

The Engineering Technology Group 16

Sign up to Betterworld.Solutions 19

Featured Environmental Projects With Video 20

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions

Welcome to Betterworld.Solutions

For the past year or more the Betterworld.Solutions project has been covering stories where business and the environment meet in order to encourage companies to understand how they can help combat global warming.

Now we have decided to reach out to people who aren’t regularly visiting the website or following our social media channels in order to provide a regular update of what’s happening in the ‘Betterworld’, and provide to anyone interested a chance to catch-up.

The stories provide a snapshot of what is happening in this space and are meant to encourage more companies, including major industries, to adopt, publish and

operate an Investment Policy to Prevent Global Warming.

In this edition we showcase the pioneers who have adopted a policy based on the template provided and who are showing the way. We also provide a selection of the Betterworld stories, ranging from the ‘heroes of Net Zero’ who are taking concrete steps to save the planet, to commentary pieces on the threat we are all facing.

Please take time to read the stories, forward your own case studies, and sign up for future editions of the Betterworld.Solutions online magazine by emailing magazine@betterworld.solutions. It’s completely free and can be distributed at will.

Have You Got 7 Minutes to Save The World?

Together

as business

leaders, we

can make a

difference.

But first, since the project began with AESSEAL®, and was the brainchild of Managing Director Chris Rea, please take the opportunity to check out his video message.

Just what is Net Zero and how do companies get there? If you want to join in but are not sure what it involves, Betterworld.Solutions is offering free online training to any company that adopts an Investment Policy to Prevent Global Warming.

The online course takes between 1-1.5 hours to complete, but participants can stop and resume – breaking it into bite-sized modules. There are also multiple choice questions to confirm understanding.

The inspiration was AESSEAL’s own journey to achieving Net Zero and the course contains real-life examples of business-friendly projects that can cut Greenhouse Gas emissions. Many of the projects have a short payback that can make them a sound investment choice by any standards.

What’s the catch? You have

got to commit to prioritizing environmentally-friendly investments that make good business sense anyway. You may also have to listen to your staff when they have ideas that will help you on the journey to Net Zero, and make decisions in a timely manner.

True, lunch is not provided, but the course is FREE. Sign up here today!

The Yorkshire Climate Change Summit 2021

Headline Sponsors

Betterworld.Solutions are proud to be headline sponsors of the inaugural Yorkshire Climate Change Summit 2021, taking place on 9 November 2021 in Leeds.

The challenge of reducing carbon emissions and safeguarding our environment for future generations will be the subject of a major conference being staged later this year.

Timed to coincide with the UK staging the United Nation’s COP 26 event in Glasgow, The Yorkshire Post is bringing the debate to the region to discuss the challenges that Yorkshire face and discuss the best way forward to achieve our shared goals.

Free online training to any company that adopts an Investment Policy to Prevent Global Warming.

4

Catch the Big Train to Net Zero

Catch

The Big

Train to

Net Zero

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions

The pump universe is a strange and wonderful place with its own ‘black holes’ and mysterious energy flows.

Steve Schofield, the Director & Chief Executive of the British Pump Manufacturers Association Ltd (BPMA) knows a thing or two about this subject. He says that virtually all the pumps out there, in commercial and public buildings, water and sewage, oil and gas, chemicals etc, are over-sized for the job.

That sounds like pouring energy into a black hole.

In this section we showcase a selection of articles on Betterworld.Solutions that have been adapted

and shortened for the magazine format to help you keep up to date.

What’s Happening?

‘Big Bang’ For Pumps?

New pumps are available that can vary their output and remain efficient, but there is a huge installed base of pumps that are wasting energy. The important issue is to know the minimum flow and pressure the system requires to operate (system need/demand). When the system demand is known, energy savings can subsequently be made, but this is a delicate engineering operation and expertise is required to ensure the objectives of the pumping system are maintained.

So while we need a reset of some sort, a Big Bang and starting over again looks unlikely without regulatory pressure or evidence of a strong business case.

Check out Steve’s ‘Green Paper’ on https://betterworld.solutions, to find out how better use of energy in the ‘pump universe’ can be down to earth, practical and planet-saving.

We can’t eat the elephant all at once but let’s tackle it one bite at a time, industry by industry, sector by sector.

The challenge for pump suppliers — so many different applications

Catch the Big Train to Net Zero

Catch

The Big

Train to

Net Zero

The petrochemical industry has been in the news recently in connection with a series of legal and shareholder backlashes related to environmental performance.

The latest corporate ‘victim’ is Royal Dutch Shell, which has been ordered by a Netherlands court to cut its carbon emissions in order to protect the environment from climate change. According to the news reports, the ruling may be the first of its kind, and it is demanding a net 45% cut in emissions by 2030 - compared with 2019 levels - to bring it in line with the Paris Agreement.

The US energy giants Chevron and Exxon are also coming under pressure. Exxon is experiencing a shareholder revolt designed to replace a couple of board members with candidates who take the threat of climate change more seriously. Meanwhile, Chevron shareholders went against board advice and voted to cut carbon emissions from the fuels they produce.

Big businesses are expert lobbyists and have superb legal teams. In addition, they pay taxes, employ lots of people and are producing goods and services on which we all depend. Shell’s Chief Executive, Ben van Beurden, has said the company should rise to the challenge and Betterworld applauds that decision. Now we need to see action to follow.

If industry as a whole is not seen as taking the environment seriously, once COVID-19

disappears from the news, we are going to hear a lot more stories about the ‘bad actors’ in big business.

The alternative to industries willingly adopting green policies is public distain, staff disengagement, and legislative reform.

Let’s remember, there are plenty of opportunities, using existing well-established technologies, that will make a huge difference, and even provide a payback.

The Clock’s Ticking - And Not Just For The Planet

If enough businesses act, together we can slow down or help to prevent Global Warming.

6

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions

Sometimes we have got to stop and think about what Net Zero and other environmental efforts are all about.

The latest news that the Amazon rainforest has turned into a net carbon producer should be a call for action for everyone interested in the future of this planet.

A report published in Nature magazine by Brazilian scientists, picked up by the Guardian newspaper and others, shows that deforestation and other human activity means that the Amazon now generates a billion tonnes of carbon a year more than it absorbs.

There is work for everyone to do to reverse the terrible downward cycle that we are on as a result of misuse of planet earth. Politicians, environmentalists, public figures

If a Rainforest Falls And No-One Listens...

and influencers from every walk of life need to join forces and put the compelling case for change.

If a tree falls in a forest and no-

one hears it, that is a philosophical puzzle. If a rainforest starts to fall and no-one listens, that is an existential threat for the human race.

Mining is an industry that gets a bad environmental press but it also produces essential raw materials that support modern living.

In today’s world, with climate change and species survival in play, it is vital that mining companies show that they understand the need to strike a better balance. The alternative means an increasingly hostile public and, potentially, a more restrictive regulatory environment.

It may seem strange to talk about finding a Hero for Net Zero in a Mexican open pit copper mine, but for our next case-study we are travelling east of Nacozari de Garcia to see what can be done, by a willing partner, with a strong environmental policy.

The Grupo Mexico Caridad mine in Mexico was experiencing lengthy downtimes and using high volumes of water to lubricate pump packing.

Digging Towards Net Zero

Due to the nature of the mine’s environment, the pumps’ impellers had to be replaced approximately every three months leading to a downtime of 12-15 hours each time.

Following a consultation with AESSEAL® the customer changed from pump packing to mechanical seals. While the harsh environment continued to cause impeller failure, the down time using mechanical seals was more than halved as installing replacements was much easier and quicker and the same seal continued to work faultlessly.

Before this change, packing was costing the customer in excess of $111,000 per year. Afterwards the cost was reduced by close to 90% to just $12,000 a year. Break-even was around two months, making the financial case alone both striking and convincing.

Even better, and vitally important

for the planet, there was a massive reduction in water usage.

8

For a nice story about how to deal with slurry, we can travel to the beautifully named Lower Fox River in Green Bay, Wisconsin, US.

Fox River recently completed a $1 billion plus, 12-year campaign to dredge 15 miles and millions of cubic metres of PCB-contaminated sludge from the bottom of the river and bay. As we know, sludge has to go somewhere.

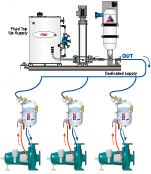

At Fox River, the slurry was pumped to a plant where the treated solids were separated from the water with eight of the world’s largest filter presses, fed by 16 Warman® 4X3 DAH slurry pumps. These pumps ramp up from near-zero pressure and high flow, to 130 psi and no flow, with each cycle, making them challenging to seal. They were originally installed as double mechanical seals with unpressurised water tanks that proved unable to maintain a stable fluid face. In other words, they ‘leaked’.

AESSEAL® was asked to redesign the sealing system at a relatively early stage. They supplied dual mechanical seals with patented pumping rings, each serviced by

Wilde About Slurry

a 25-litre barrier tank that syphons the heat away from the seals and supplies the missing ‘stable fluid film’. No more leaks.

Using the new system, there were ZERO seal failures during the remainder of the operational period from 2011 to 2020 and any preventive maintenance was carried out when the plant was idle. In addition, the system consumed only 25 gallons of water (less than 100 litres) per year in total.

Over the period 2009 – 2020, almost 6 million cubic metres of sludge was dredged and nearly 10 billion US gallons (38 billion litres) of water was treated and restored to the river.

On this project, the double mechanical seals, tank system, and water pressurisation skid eliminated the down time and costs associated with mechanical seal failures, while at the same time providing a safe and reliable sealing method that does not require any gland packing water that would dilute the de-watering process.

This is an important chapter in the Fox River PCB cleanup effort, which

began over 20 years ago and is one of the largest ever undertaken worldwide. Now the original project website has been shut down after the Lower Fox River was handed over to the Wisconsin Department of Natural Resources.

As Oscar Wilde said this is what machines are for – “man is made for something better than disturbing dirt.” It is up to us to make the machines work for us.

Typical arrangement of pumps, seals, and tanks that are serviced by a single self-contained water pressurisation skid. At the Fox River project, 16 Warman® pumps are serviced by one pressurisation skid.

“nearly 10 billion US gallons (38 billion litres) of water was treated and restored to the river”

We all need electricity, but we shouldn’t waste it. That’s why Betterworld.Solutions was thrilled when Dr Alex Mardapittas of Powerstar agreed to share some of the company’s research and their real life case studies on https://betterworld.solutions.

So what is voltage optimization, and why is it helping to save the planet?

To put it simply, this is an energy saving technology that is used to regulate, clean and condition the incoming power supply in order

The Soft Power Of Voltage Optimization

to reduce the voltage supplied to the optimum level for the on-site electrical equipment and appliances.

If cost-effective voltage optimization (VO) was installed

throughout the UK it could potentially save 11,760 tonnes of CO2 a day, assuming a 7% saving. This would be 4,292,400 tonnes of CO2 a year or the equivalent of taking nearly one million cars off the road.

4,292,400 tonnes of CO2 a year

The news that the UK Government has banned the sale of halogen

lightbulbs from September 2021 under climate change plans

should not be regarded as either a surprise or a threat.

The process of phasing out higher energy halogen bulbs,

such as those used in business and industry, started in

2018 under EU-wide rules.

There is usually a bit of fuss accompanying this kind

of change, but it makes perfect sense to switch to

energy saving lighting technology. According to the

government, the move will cut 1.26 million tonnes

of carbon emissions a year and deliver savings for

consumers. LED lighting already accounts for two-thirds

of new lights sold in Britain.

Office and factory lighting carries a significant business

cost both in energy use and maintenance. LED lighting

provides high brightness and instantaneous illumination as

well as longer life leading to less maintenance. Another major

benefit is that energy saving can be achieved by using LED in

combination with controls such as occupancy sensors.

To take one example, throughout AESSEAL’s Global Headquarters in Rotherham and at the Bradford branch, lighting has been upgraded from fluorescent to LED and controls. In one year the installation achieved savings of 48,800 kWh and the return on investment was 4.2 years.

Lights Out For Halogen

The news that the UK Government has banned the sale of halogen

lightbulbs from September 2021 under climate change plans

should not be regarded as either a surprise or a threat.

The process of phasing out higher energy halogen bulbs,

such as those used in business and industry, started in

2018 under EU-wide rules.

There is usually a bit of fuss accompanying this kind

of change, but it makes perfect sense to switch to

energy saving lighting technology. According to the

government, the move will cut 1.26 million tonnes

of carbon emissions a year and deliver savings for

consumers. LED lighting already accounts for two-thirds

of new lights sold in Britain.

Office and factory lighting carries a significant business

cost both in energy use and maintenance. LED lighting

provides high brightness and instantaneous illumination as

well as longer life leading to less maintenance. Another major

benefit is that energy saving can be achieved by using LED in

combination with controls such as occupancy sensors.

To take one example, throughout AESSEAL’s Global Headquarters in Rotherham and at the Bradford branch, lighting has been upgraded from fluorescent to LED and controls. In one year the installation achieved savings of 48,800 kWh and the return on investment was 4.2 years.

Lights Out For Halogen

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions

10

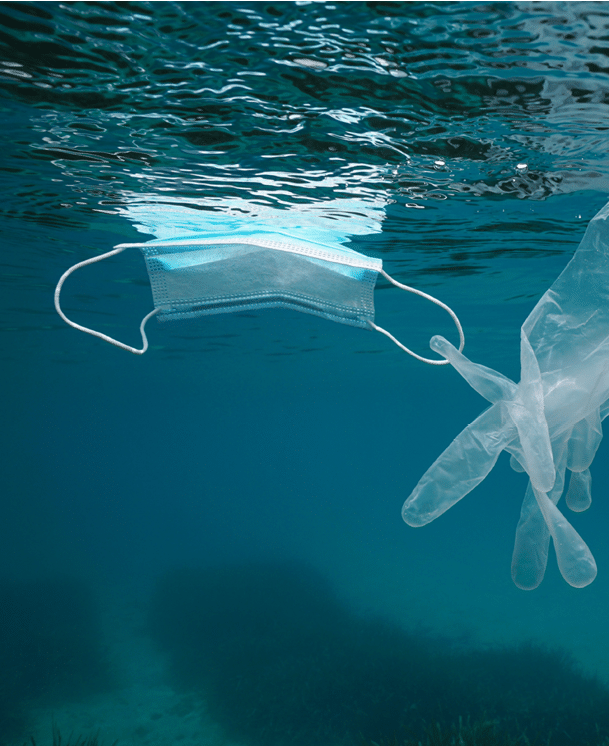

A mountain of disposable masks, plastic gloves, and medical gowns is being tossed away every single day, much of it procured from China in hurriedly arranged contracts that are putting pressure on health service resources all over the globe.

But, while the dash to combat this terrible pandemic meant shortcuts were taken, it is also important to understand that taking a short-term viewpoint is also very damaging to the planet.

In this context, Betterworld.Solutions was glad to welcome a contribution from http://www.madeherenow.com on a UK scheme to fit protective clothing to environmental goals, which unfortunately seems to be dead in the water.

The Monstrous Problem of Covid Waste

The articles, by Peter Marsh, highlight the fact that in recent years, most medical gowns and other items of personal protective equipment used in Britain have been single-use, mainly because extremely cheap disposable gowns have been available from low-cost countries.

This case suggests that in the UK alone, at the current rate of usage, medical gowns would generate more than 400 tonnes of waste a week, the equivalent of about 35 double-decker buses.

This is a global issue, not just a UK-domestic problem. In this respect the series of articles on this topic which have now joined the case studies on ‘Betterworld’, deserve to be closely examined by procurement authorities and

decision-makers

everywhere.

We need to break

out of the tunnel vision

that means we do things

the way they have always been done, and measure success, not just in terms of the lowest unit cost, but also taking into account the cost to the planet.

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions

Companies Signed Up

As of September 2021, 15 companies are endorsing the Investment Policy to Prevent Global Warming

• AESSEAL®

• BPMA

• Powerstar®

• Evenort

• Gripple®

• Wandisco

• OSL Group

• Vuclan Seals

• Rototherm™

• Whyy? Change

• Eastern Seals

• DMG Mori

• Helix®

• Engineering Technology Group

• Britcon

Did you know that you could see a return on investment whilst helping

to save the environment?

Company Introduction

AES Engineering Ltd, including its main UK business AESSEAL®, with its Rotherham headquarters, has 230 locations worldwide, supplying customers in 104 countries, and employs a global network of sales engineers and technical support specialists. The designers and manufacturers of mechanical seals, bearing protectors, seal support systems and gland packing which maximize rotating equipment up-time employ more than 1,800 people across the globe.

Beyond Net Zero

The group is proud to announce that the impact of its UK

operations had a net beneficial impact on the environment in 2020 and that it has pledged £29 million of ‘planet-friendly investment’ by 2029 to push beyond Net Zero for its global business.

Following the achievement of Net Zero in AESSEAL®, for Scope 1 and 2 emissions, including direct

and indirect energy use and business travel, the company sought independent verification of the indirect Scope 3 emissions for the UK buisness, as well as the balancing impact of the emissions avoided by use of the company’s products in major industry.

Separate evaluations were carried

out on Scope 3 emissions, which include indirect emissions in the company’s value chain, and on the emissions avoided by the installation of just one of the company’s leading edge reliability products.

The independent consultants verified that AESSEAL’s Scope 3 indirect emissions amounted to 46,300 tonnes of CO2e in 2020. They also separately verified that the emissions avoided, on just some selected projects, totalled 64,200 tonnes of CO2e.

AES Engineering’s plan to ensure that it met the target of Net Zero for the Global Group by 1st April 2029 has now been accelerated, building on actions such as the investment policy for electric vehicles in December 2020, and the creation of an innovative nature walk on its headquarter site. The engineering group says it is now almost certain it will move beyond Net Zero for the global group by 2022 but will continue investing a total £29 million

AES Engineering Ltd

12

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions

in ‘planet-friendly investments’ by 2029 to get well beyond this target.

Originally the company’s Rotherham Head Office site was a tip for slag that was taken off the top of the melt in steel blast furnaces. A significant proportion of the site has been turned into a nature reserve and even 20 years ago the business won wildlife awards for the environment around its Rotherham base.

In some recent news, AESSEAL plc

has won the Sustainable/Ethical Manufacturer Award at the Made in Yorkshire Awards as a result of its commitment to mitigate climate change.

The latest award for the Yorkshire precision engineering company pre-dates the latest series of environmentally-led investments, including its decision to spend £566,000 on fitting solar panels to the roof of its Mill Close factory, in order to reduce the total amount of electricity consumed at the site by a

further 22%.

This follows a £183,000 purchase of energy-saving amorphous core transformers. This technology reduces energy losses on the power transformation required for powerful industrial equipment such as computer-controlled lathes from 5.1% to less than 1%.

In a unanimous Board decision the company will be promoting its ‘£29 million by 2029’ commitment in order to set a new ‘gold standard’ for business engagement in the battle against global warming.

AESSEAL plc backs Raleigh Re-Green Project

Meanwhile, AESSEAL® is donating £5,000 to help fund some of the next generation of young conservationists taking part in Raleigh International’s first ever UK program, which is focused on preserving the Scottish rainforest.

Only 30,000 hectares of Scottish rainforest remain, but this is threatened by overgrazing, invasive plant species, tree disease, air pollution and climate change.

Raleigh’s Re-Green project will support ‘rewilding’ work, helping to protect the vulnerable ecosystems. The volunteers will undertake technical training in mobilizing their communities and will join the global youth-led movement ‘Action Not Excuses’.

While the volunteers work for free, their food, accommodation and other expenses have to be met and as part of the Re-Green program, Raleigh aims to fund 30 young people from underprivileged and under-represented backgrounds.

Net Zero and beyond for the Global Group

Britcon

Company Introduction

A family-owned business based in Scunthorpe and Wakefield, Britcon are a leading Civil Engineering, Building and Steelwork solutions company, delivering a complete built environment service to our customers and future generations, whilst maintaining important traditional skills. We understand and welcome new modern methods leading the way in delivering sustainable, safe, innovative and value driven solutions without compromising on quality.

Britcon has become a preferred and trusted partner for many local authorities, public departments and blue-chip clients in both the private and public sector. Our diverse skill set allows us to deliver in many key industry sectors in civil engineering, building and steel solutions, creating a true turnkey delivery solution for the clients we work with.

At Britcon, we’re committed to sustainability and seek to conduct our business in a manner that minimizes environmental impact and conserves natural resources. Working closely and collaboratively with our suppliers and customers, we have built up a track record of delivering successful sustainable projects.

Why Britcon adopted the Betterworld Policy

Britcon have signed up to Betterworld because we believe that achieving true sustainability for our industry will require collaboration and knowledge sharing across our industry and beyond, and we believe that Betterworld offers an excellent platform for this. We feel that sustainability must become part

of our everyday decision making and project delivery processes and we are excited to make that commitment in our sustainability policy and to also join a community of like-minded organizations.

Britcon creating a Betterworld

Re-Food, Widnes

A £20million Anaerobic Digestion Plant in Widnes, designed to recycle around 90,000 tonnes of commercial and domestic food waste and generate up to 17NWhs of biogas, with energy transported directly to the national gas grid to provide enough power for up to 8,000 homes. This project followed a similar project in Doncaster and proceeded another similar project in Dagenham.

Industrial Space, Hereford

A £6million enterprise park in Hereford consisting of 17,000 sq. ft of industrial space and 18,000 sq. ft of office space benefiting from sustainable solutions including solar PV and electric car charging points.

Church Square, Scunthorpe

A £3.5million office development in Scunthorpe, which included construction of a new office block and the redevelopment and extension of an existing office block. The project focused on renewable energy systems comprising PV panels, air source heat pumps and intelligent Building Management Systems.

14

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions

DMG Mori

Company Introduction

DMG MORI AKTIENGESELLSCHAFT is a worldwide leading manufacturer of machine tools. Our integrated automation and end-to-end digitization solutions extend the company’s core business with turning and milling machines, Advanced Technologies (Ultrasonic, Lasertec) and Additive Manufacturing.

Our mission: To support our customers – in their production and in digitization! Our aspiration: we want to be the most appealing machine tool maker with digital and sustainable products worldwide. Our motivation: continuous innovation for a better world.

Sustainability and technological leadership go hand in hand at DMG MORI. To protect the climate and environment we pursue a 360-degree approach: We take action along all segments of our value chain. All our innovations and decisions have one common goal: prevent the waste of resources – for us and our partners. Our initiatives about climate neutrality are divided into three parts:

– GREENMACHINE: climate neutral footprint of all DMG MORI machines*

– GREENMODE: energy and carbon efficient machine operation

– GREENTECH: technology Excellence for green technologies.

Already since May 2020 DMG MORI has a climate neutral Company Carbon Footprint. All machines delivered worldwide since January 2021 are – along the entire supply chain – completely carbon neutral (Product Carbon Footprint). with the

triad ‘Avoid. Reduce. Compensate’ with climate protection certificates.

Why DMG MORI adopted the Betterworld Policy

Sustainability and technological leadership go hand in hand at DMG MORI AKTIENGESELLSCHAFT. We are already at the leading edge in many areas across all industries and also want to contribute to preventing global warming through technological change and investment decisions. Our commitment to sustainability is taken into account for every business decision: Investing in climate is investing in the future. In terms of capital investment, we will consistently put sustainable projects first. We are proud to communicate this to all our stakeholders and interested parties. In addition, we explicitly encourage our employees to pro-actively suggest new investment ideas and to become active themselves. Our Investment Policy to Prevent Global Warming is therefore also a tool that clearly and concisely communicates our own commitment to climate and the environment. We take on responsibility.

“We assume responsibility in a holistic manner – for our company, for our products and in cooperation with our customers, partners, and suppliers. Sustainability is of utmost importance to DMG MORI in all business activities and decisions – including investments. Too much commitment to sustainability is impossible.”

Dr. Maurice Eschweiler, Chief Representative

DMG MORI creating a Betterworld

Sustainability has been a focus at DMG MORI for many years: We want to act in an environmentally friendly and resource-saving manner in all areas – along our entire value chain. In doing so, we rely on the triad: ‘Avoid. Reduce. Compensate.’ Some examples: energy-efficient new buildings and refurbishments, LED lighting, modern heating, ventilation, and cooling systems, or renewable energy generation. This year alone, a further 26 individual energy efficiency measures have been implemented. To this end, we are investing in eight locations in Germany, Italy and Poland – investments that are beneficial to the environment and at the same time pay for themselves quickly. This is because new insulation, LED lighting, intelligent circuitry and more efficient air compressors will save 4,000 MWh of energy per year in the future – and thus over 12,300 t of CO2. This corresponds to a saving of around 25% of our total ‘Company Carbon Footprint’ from 2019! One example: At the Bielefeld site, we have tackled the replacement of the air compressors. Compressed air is the most expensive energy source in production with comparatively high emissions – a good lever to reduce CO2 emissions and save costs at the same time. Adapting to the Investment Policy to Prevent Global Warming realized this measure.

The Engineering Technology Group

Company Introduction

The Engineering Technology Group (ETG) brings together the strengths of the world’s most advanced manufacturers of high technology machine tools, automation, additive manufacturing, wire EDM and work-holding systems to deliver highly productive and effective metal cutting solutions.

ETG delivers a new kind of thinking to the machine tool market by providing in-depth technical support and applying unrivalled insight, experience and expertise. With this, ETG maximizes the benefit from your new investment with a bespoke manufacturing solution that is tailored to your needs.

Our commitment is to offer exceptional customer service, in-depth product knowledge and factory trained support teams as well as on-going service. This is all delivered to the highest standards, as expected from our renowned associates.

ETG is a single-source machine tool and additive manufacturing turnkey solutions provider that delivers the best manufacturing solutions for increasing productivity and profitability. ETG is your partner; supporting your business every step of the way. We are dedicated to making engineers champions.

Why ETG adopted the Betterworld Policy

ETG has always had an emphasis on best practice, sustainability and the environment. Having the opportunity to align our business ambitions and corporate responsibility framework with that of a valued customer through the Investment Policy to Prevent Global Warming makes perfect sense for ETG.

Our ambition is to create a sustainable environment for future generations. Our aim is to deliver this sustainability whilst reducing costs and improving best practice for both our business and that of our valued clients.

“Our corporate responsibility to sustainability is imbued in the very heart of our business. ETG is on a journey of continuous improvement where all business divisions and employees are participating in training courses to raise awareness and create cost reductions, business improvements and improved environmental performance – both internally and throughout our supply chains and customer base.”

Martin Doyle, Group Managing Director

ETG creating a Betterworld

ETG’s technical partners have long been implementing ground-breaking energy efficiency technology such as the Chiron spindle energy recovery system among others. However, as part of this ongoing journey, ETG is taking its commitment to both its supply chain and customers to support UK manufacturers on their journey to reducing emissions and waste with the benefit of reducing

business costs and improving environmental credentials. One example of this is the new Powerstar transformers that ETG has now introduced.

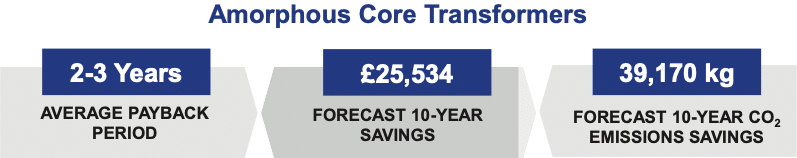

The new Powerstar Amorphous Core Transformers will be available for all machines purchased from ETG and the transformers can drastically reduce machine running costs, emissions and improve efficiency. Despite the initial cost of Amorphous Core Transformers being slightly higher than conventional transformers, over a 10-year period, the new Amorphous Core Transformers yield an average saving of £25,500 with a CO2 emission reduction of almost 40,000kg. This is because conventional transformers consume their initial purchase cost in wasted energy every 9 months. In comparison, the new Amorphous Core Transformers are significantly more efficient and waste minimal amounts of energy. Proudly designed and manufactured in the UK, manufacturers can now find out more information on the new Powerstar Amorphous Core Transformers from ETG.

16

Amorphous Core Transformers will be available on all ETG supplied machines

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions

Gripple®

Company Introduction

At Gripple®, we are a market leading manufacturer of suspension, tensioning and anchoring solutions in the Industrial and Agricultural sectors. A 100% employee-owned company, Gripple® has a unique approach to business, characterized by investment in people, innovation and sustainable growth.

Why Gripple® adopted the Betterworld Policy

Showing our commitment to future projects to help prevent global warming through technological change is at the forefront in Gripple’s plans. We encourage all our global stakeholders and employee shareholders to assist with the implementation of sustainable projects and to help identify future opportunities to reduce our carbon footprint.

Gripple® creating a Betterworld

Gripple Ltd is a Sheffield manufacturer of wire joining, and tensioning devices. We acquired Norfolk Bridge Works site in January 2019, with the objective of building a new factory for its fledgling Automation business.

The site on the junction of Foley Street and Leveson Street was a derelict piece of land which had not been used since 1959. The site was originally used as a foundry and boiler maker and was owned by Davy Brothers.

Gripple® aimed to build an inspirational, green building which would inspire our employees and be a beacon for smart manufacturing in Sheffield. After investing £3.5 million in the development, we have achieved our aim of developing a green, inspirational building.

Our Norfolk Bridge Works site is BREEAM Excellent. It has 440 solar panels servings the factory and providing 30% of our energy requirements. Included in this building, is a state-of-the-art heating and lighting system as well as a fully controlled Building Management System.

We aim to make our buildings inspiring places to work and through innovative features like green living walls, and the use of creative colour – we create great environments to work in.

“Our desire to create iconic buildings is always tempered by being a traditional Yorkshire business where every penny counts. For our fifth

Sheffield city region factory we used our tried and trusted strategy. David Bowling challenges us with inspirational designs which are then translated into reality by Design Team Partnership and Eastwoods. We have been able to meet the concept design brief and to deliver the project to budget and time-scales which were extended due to Covid.”

“we have achieved our aim of developing a green, inspirational building”

Company Introduction

Whyy? Change is a leading apprenticeship and training provider based in Sheffield, that aims to provide knowledge and services to transform people and industry. They empower individuals to transform their business mindset and question their thinking through a range of bespoke channels including; Lean & Six Sigma, Leadership (CMI), Marketing (CIM), Quality HSE (Bureau Veritas) and HR (CIPD) training in the South Yorkshire region. They employ skilled practitioners who are experts in their fields, enabling them to ask the right questions about an employer’s purpose, ambition, opportunities, challenges and barriers to success. Whyy? Change is also a registered study centre for Chartered Institute of Marketing (CIM), Chartered Management Institute (CMI), Chartered Institute of Personnel Development (CIPD) Pearson Edexcel, Lean6 and a partner with Bureau Veritas, the global leader in certification to deliver their Quality – ISO9001, Environmental ISO14001 and Health & Safety ISO45001 training courses and consultancy. These partnerships provide added value to their learners by embedding them within each program at no extra cost to their customers.

Why Whyy? Change adopted the Betterworld Policy

Whyy? Change believes in leading the change no matter the size of the organization. Being a leader and not a sheep will convince other like-minded businesses to start their net-zero journey.

Whyy? Change

Whyy? Change creating a Betterworld

Our vision is to provide business knowledge & services to transform people and industry with a preferred delivery model based on face-to-face engagement with hard copy training materials. Since committing to the sustainability policy, we continue to be challenged to think differently about the learner experience. As a strong believer in defaulting to physical learning materials, it has given us the opportunity to re-shape how the customer can still have the same experience, wihtout always having to rely on the need for paper-based resources. In the grand scheme, this is a small personal change but the change in mindset does stop us in our tracks and question how we should design and deliver the right solution the right way.

Our approach & brand awareness for the company has recently had an injection of time, creativity, and money. The result of our investment in marketing has meant we still retain the physical brochures but have

changed our approach to engaging. This included:

• Re-design the website so the customer can assess all information in a convenient manner

• Identify a commercial printing partner based on their investment in sustainability

• Where possible we ‘nudge’ them to access information directly from the website, and only as a last resource to take a physical copy.

Again, our commitment ensured that we identified a commercial printer that was able to provide environmentally friendly materials.

“Having any policy is about commitment. Our sustainability policy is about leading on the challenge of our time. We are small and we don’t make stuff, so people may feel it doesn’t fit. It really does fit and we want to lead by playing our part.”

Ray Byrne, CEO

18

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions

As we continue to experience temperature rises throughout the world, recent research shows that the number of extremely hot days every year when the temperature

reaches 50ºC has doubled since the 1980s. It’s vital that industry leaders come together now, to help reduce C02 emissions.

We estimate that widespread adoption of climate-friendly polices in industry globally, could have the equivalent impact of taking 529.5 million cars off the road. If we all take action now, we will help to create a better world for the next generation.

So sign up today...

Featured Environmental Projects With Video

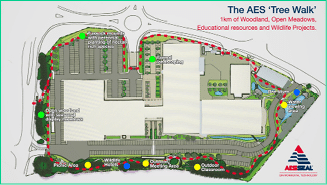

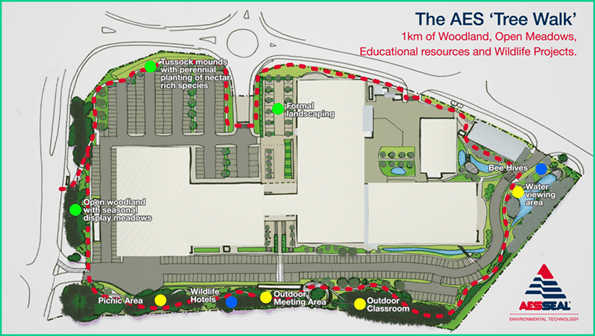

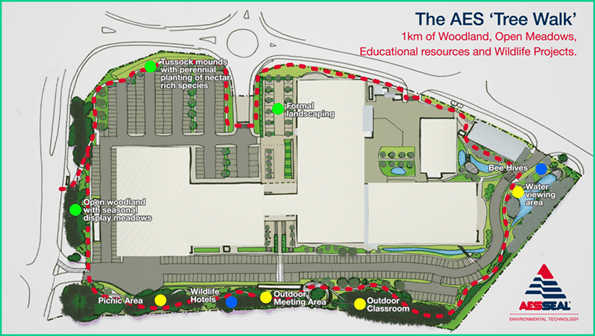

The AESSEAL® Tree Walk Project

Tree Walk consists of 1km of woodland and open meadows to support local wildlife. Additionally there are bird boxes, an insect hotel, hedgehog habitats and two bee hives containing 60,000 honey bees. An outdoor meeting area and picnic area will also be included to support the health and well-being of employees and visitors.

Find out more about the AESSEAL® ‘Tree Walk’ vision

1km of woodland and open meadows to support local wildlife

20

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions

The AESSEAL® Hedgehog Release

In the last 13 years the population of hedgehogs in the UK has declined by at least 45%, according to The Mammal Society. This has led to hedgehogs becoming a vulnerable species at risk of extinction.

To help preserve the species, AESSEAL® has invested in a conservation effort, welcoming 25 hedgehogs at the Global Headquarters in Rotherham.

Working alongside a hedgehog hospital, AESSEAL® has established

a safe environment for the hedgehogs. This includes broadleaf planting, meadow seeding, feeding stations and much more. All this has the purpose of giving the hedgehogs the best possible opportunity to thrive in the Wetlands area.

Find out more about the AESSEAL® Hedgehog Release

Special thanks go to all the businesses that have endorsed Betterworld.Solutions and have contributed to this issue and to those whose case studies are providing an example for all of us.

We are actively seeking new businesses to showcase in order to have more diversified content, and generate synergies among like-minded companies who value the future of this planet.

Download An Investment Policy to Prevent Global Warming at:

https://betterworld.solutions